NOT A PHYSICAL PRODUCT!

DOWNLOADABLE 3D PRINT FILE ONLY!

!!! PLEASE READ THE DESCRIPTION BELOW CAREFULLY !!!

Ages 15+! Not suitable for children! Small parts can be swallowed!

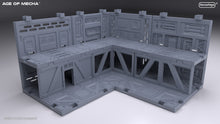

35 unique set elements to build your own sci-fi hangar/base diorama/play set.

PRE-SUPPORTED CHITUBOX V1.9.0 FILES INCLUDED!

download Chitubox V1.9.0 here:

https://www.chitubox.com/en/index

Images show color proposals.

The download files will be provided in *.rar compression file archives.

To unpack the file contents, either use WinRar (winrar.de) for windows, or The Unarchiver App (Apple App Store) for Mac OS. Both applications are free of charge.

1/35 scale printable parts, snap fit assembly, no glue required.

Figure height: approx. 2 inch / 5 cm

The parts come in pre-supported Chitubox files and STL file format (for all other printers, SLA, DLP and FDM).

We highly recommend to choose SLA or DLP printers!

FDM prints usually do not show the very fine detail, unless you scale up the parts.

For SLA/DLP printers, we highly recommend to use the Resione M58 or Resione TH72 or Anti-Impact resins.

Resione M58 ResioneTH72 Resione Anti-Impact

For near perfect prints, use the following settings:

Bottom Layers: 5

Bottom Layer Exposure Time: 50 seconds

Standard Layer Exposure Time: 4.0 seconds

Leave all other settings as recommended by the resin manufacturer:

https://www.resione.com/pages/settings

For transparent glass parts, use Resione G217 transparent clear resin:

Resione G217

with a layer exposure time of 4.0 seconds.

After post UV curing, submerge the transparent parts in a cup of hot water for about 5 minutes to reduce the yellowing effect.

To receive full transparency and a clear and glossy glass effect, apply at least one layer of glossy clear coat with airbrush.

Wash the parts in IPA (70%-99%) for 20 minutes.

UV post cure the parts: M58/G217: 20 minutes

TH72: 60 minutes

Anti-Impact: 60 Minutes at 70° Celsius

Assemble the parts after curing, to avoid dusting/powdering of the resin surface!

The joint fits are quite tight in the beginning, so make sure to wiggle the parts together slowly and carefully to avoid breaking parts.

Should you still struggle to assemble the snap fit joints, place the parts in hot water for 30 seconds to soften them a bit, then assemble.

Some printed resin tends to shrink over time (the process can go on several weeks after print) until it has fully settled it's properties.

If the joints come loose, use small portions of modelling clay, like super sculpey to fill in the gaps.